Individual Report (80%)

While each individual answer might have a different word count from the others, the overall word count should not exceed 2,000 (+ or – 10%) words excluding calculations (numbers and equations, etc.).

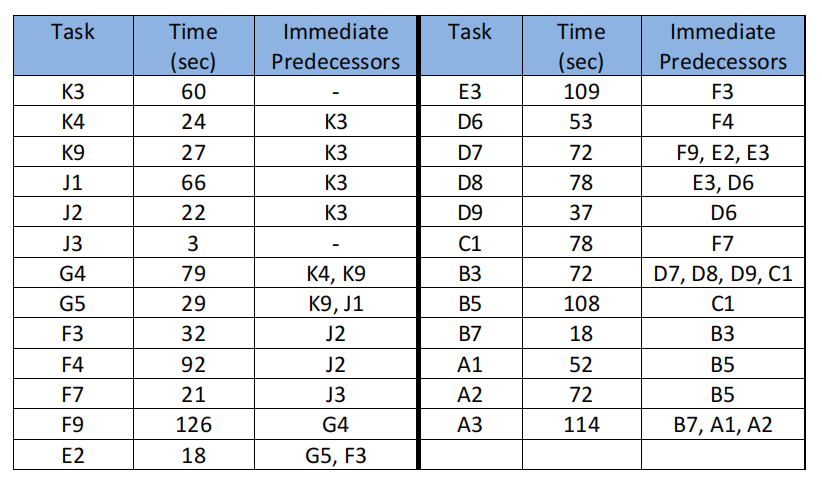

Q1. (20%) As the Cottrell Bicycle Co. of St. Louis completes plans for its new assembly line, it identifies 25 different tasks in the production process. VP of Operations Jonathan Cottrell now faces the job of balancing the line. He lists precedences and provides time estimates for each step based on work-sampling techniques. His goal is to produce 1,000 bicycles per standard 40-hour workweek.

G5, F3[BUS002] Operations Management Dr Eun-Seok Kim

2

a) Balance this operation using shortest operation time rule and compute the efficiency of the line. (10%)

b) Discuss how this balance could be improved. Is it possible to improve this balance to 100%? (10%)

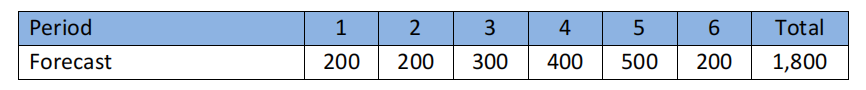

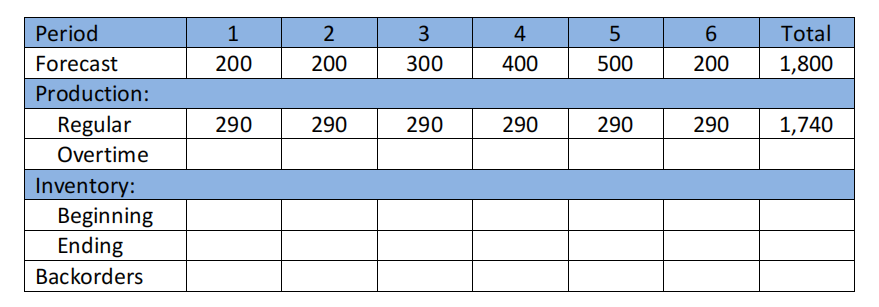

Q2. (20%) Planners for a company that makes several models of skateboards are about to prepare the capacity plan that will cover six periods. They have assembled the following information.

They intend to start with zero inventory on hand in the first period, and their production rate is 290 units per period. Use overtime at a fixed rate of 20 units per period as needed. Plan for an ending inventory of zero for period 6. Backorders cannot exceed 90 units per period.

a) Prepare the capacity plan as below. (10%)

b) Compare and contrast two simple pure strategies, i.e., chase strategy and level strategy, for capacity planning. (10%)

Q3. (20%) Emarpy Appliance is a company that produces all kinds of major appliances.

Bud Banis, the president of Emarpy, is concerned about the production policy for the company’s best selling refrigerator. The annual demand has been about 8,000 units each year, and this demand has been constant throughout the year. The production capacity is 200 units per day. Each time production starts, it costs the company £120 to move materials into place, reset the assembly line, and clean the equipment. The holding cost of a refrigerator is £50 per year. The current production plan calls for 400 refrigerators to be produced in each production run. Assume there are 250 working days per year.

a) If the company produces 400 refrigerators at a time, what would the total annual setup cost and holding cost be? (10%)[BUS002] Operations Management Dr Eun-Seok Kim

3

b) If Bud Banis wants to minimize the total annual inventory cost, how many refrigerators should be produced in each production run? How much would this save the company in inventory costs compared to the current policy of producing 400 in each production run? (10%)

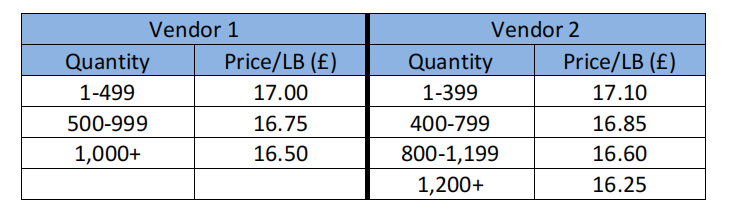

Q4. (20%) Emery Pharmaceutical uses an unstable chemical compound that must be kept in an environment where both temperature and humidity can be controlled.

Emery uses 800 pounds per month of the chemical, estimates the holding cost to be 50% of the purchase price (because of spoilage), and estimates order costs to be £50 per order. The cost schedules of two suppliers are as follows:

a) What quantity should be ordered, and which supplier should be used? (10%)

b) Discuss factor(s) should be considered besides total cost. (10%)

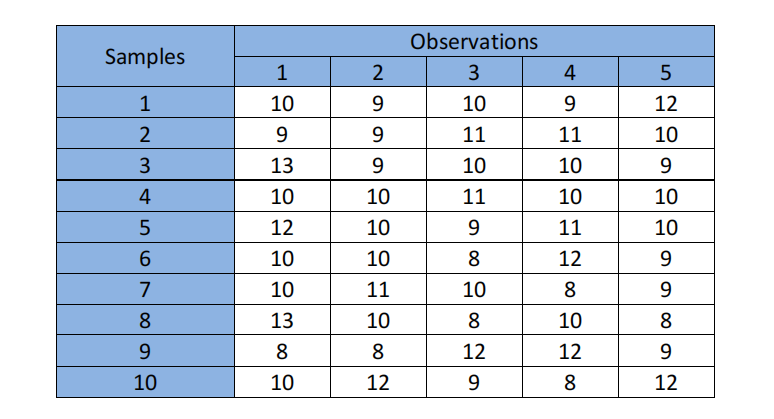

Q5. (20%) A process considered to be in control measures an ingredient in ounces. A quality inspector took 10 samples, each with 5 observations as follows:

a) Using this information, obtain three-sigma (i.e., z=3) control limits for a mean control chart and control limits for a range chart, respectively. It is known from previous experience that the standard deviation of the process is 1.36. (10%)

b) Discuss whether the process is in control or not. (10%)

Leave a Reply